Mechanical Pump Fitter Jobs Near You Start 2024 Today

Mechanical Pump Fitter Jobs are essential in various industries, providing the backbone for maintaining and repairing vital machinery. These skilled professionals ensure that mechanical pumps, which are crucial for numerous applications, operate efficiently and reliably. Without them, many sectors, including oil and gas, water treatment, and manufacturing, would face significant operational challenges.

Understanding the Role

What Does a Mechanical Pump Fitter Do?

A mechanical pump fitter is responsible for installing, repairing, and maintaining mechanical pumps. These pumps are used Mechanical Pump Fitter Jobs to move liquids, gases, or slurries through a system. The role requires a deep understanding of mechanical systems and the ability to diagnose and fix issues efficiently.

Key Responsibilities

- Installing mechanical pumps and associated components

- Performing routine maintenance and inspections

- Troubleshooting and repairing pump malfunctions

- Reading and interpreting technical drawings and specifications

- Ensuring all work complies with safety standards and regulations

Skills and Qualifications

Essential Skills for Mechanical Pump Fitters

To excel as a mechanical pump fitter, one needs a blend of technical and soft skills:

- Strong mechanical aptitude

- Proficiency in using hand and power tools

- Ability to read and interpret technical documents

- Excellent problem-solving skills

- Attention to detail and precision

Required Qualifications and Certifications

Most employers require candidates to have:

- A high school diploma or equivalent

- Vocational training in mechanical or industrial technology

- Relevant certifications, such as the Certified Pump Technician (CPT) credential

- Apprenticeship experience or on-the-job training

Training and Education

Educational Pathways

Aspiring mechanical pump fitters typically start with a high school diploma, followed by vocational training in mechanical engineering or industrial technology. Courses in mathematics, physics, and blueprint reading are particularly beneficial.

Apprenticeships and On-the-Job Training

Many mechanical pump fitters enter the field through apprenticeships, which combine classroom instruction Mechanical Pump Fitter Jobs with hands-on experience. Apprenticeships provide a thorough grounding in the practical aspects of the job, ensuring that fitters are well-prepared for the challenges they will face.

Types of Mechanical Pumps

Overview of Different Pump Types

Mechanical pumps Mechanical Pump Fitter Jobs come in various forms, each suited to specific applications. The main types include:

- Centrifugal Pumps

- Positive Displacement Pumps

- Gear Pumps

- Diaphragm Pumps

Specifics of Each Type

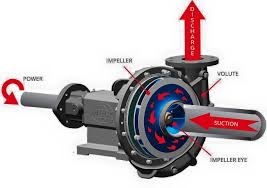

Centrifugal Pumps: Commonly used for water, sewage, and petrochemicals, these pumps use rotational energy to move fluids.

Positive Displacement Pumps: Ideal for high-viscosity fluids, these pumps displace a fixed amount of fluid per cycle.

Gear Pumps: Used for hydraulic fluid power applications, gear pumps are known for their precision and efficiency.

Diaphragm Pumps: Often used in chemical processing, these pumps handle corrosive and abrasive fluids well.

Industries Employing Mechanical Pump Fitters

Oil and Gas Industry

In the oil and gas sector, mechanical pump fitters are crucial for maintaining the pumps that transport crude oil and natural gas from extraction sites to processing facilities.

Water Treatment Plants

Mechanical pump fitters ensure that the pumps in water treatment facilities operate smoothly, playing a vital role in water purification and distribution.

Manufacturing and Industrial Sectors

Manufacturing plants rely on mechanical pumps for various processes, including cooling, lubrication, and fluid transfer. Fitters keep these systems running efficiently.

Day-to-Day Activities

Typical Workday for a Mechanical Pump Fitter

A typical day for a mechanical pump fitter involves inspecting pumps, performing routine maintenance, and responding to Mechanical Pump Fitter Jobs emergency repair calls. Tasks can range from replacing worn-out parts to aligning pump components.

Tools and Equipment Used

Fitters use a variety of tools, including:

- Wrenches and screwdrivers

- Hydraulic jacks

- Precision measuring instruments

- Welding and soldering equipment

Work Environment

Conditions and Settings

Mechanical pump fitters work in diverse environments, from outdoor oil rigs to indoor manufacturing plants. The job can be physically demanding, often requiring fitters to work in cramped or elevated spaces.

Safety Precautions and Regulations

Safety is paramount in this field. Fitters must adhere to strict safety protocols, including wearing personal protective equipment (PPE) and following guidelines to prevent accidents and injuries.

Career Progression

Entry-Level to Senior Positions

Entry-level fitters typically start as apprentices or junior technicians. With experience, they can advance to senior fitter positions, supervisory roles, or specialized areas such as pump design and engineering.

Opportunities for Advancement

Advancement opportunities often include further training and certification, taking on more complex projects, or moving into management positions.

Salary Expectations

Average Salaries

The average salary for a mechanical pump fitter varies by region and experience but generally ranges from Mechanical Pump Fitter Jobs $40,000 to $60,000 per year.

Factors Influencing Pay

Factors that influence pay include:

Level of experience

Mechanical Pump Fitter Jobs In Pakistan Free 2024 From pakjob.info The Links Are Given Below!